Industry Knowledge Extension

Acrylic pressure sensitive adhesives (PSAs) are a type of adhesive that become sticky and adhere to surfaces when pressure is applied. They are made from acrylic polymers and can be formulated with a variety of additives to achieve specific properties such as viscosity, tack, and adhesion strength.

Acrylic PSAs have several advantages over other types of adhesives. They have good resistance to aging, UV radiation, and weathering, and they can maintain their adhesive properties over a wide range of temperatures. They are also generally non-toxic and non-flammable.

Acrylic PSAs are commonly used in a wide range of applications, including tapes, labels, graphics, and medical devices. They can adhere to a variety of substrates, including plastics, metals, and glass, and can be used for both permanent and temporary bonding.

The properties of acrylic PSAs can be tailored to meet specific application requirements by adjusting the composition and formulation of the adhesive. This allows for a high degree of customization to ensure optimal performance in different environments and under different conditions.

There are several advantages of using acrylic pressure sensitive adhesives over other types of adhesives:

Good aging and weathering resistance: Acrylic PSAs are highly resistant to aging and weathering, which means they can maintain their adhesive properties over time and under exposure to different environmental conditions.

Versatile bonding: Acrylic PSAs can adhere to a wide range of substrates, including plastics, metals, glass, and fabrics.

Temperature resistance: Acrylic PSAs can perform well over a wide range of temperatures, making them suitable for use in both high-temperature and low-temperature applications.

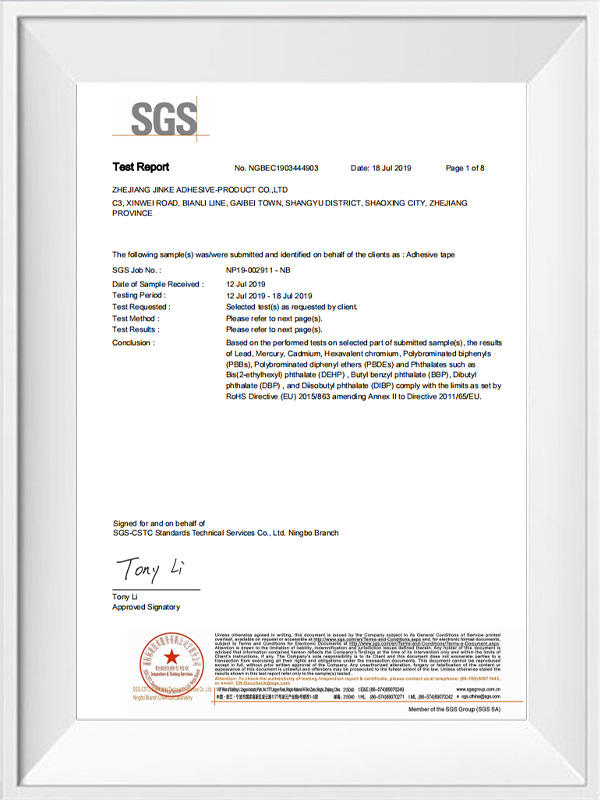

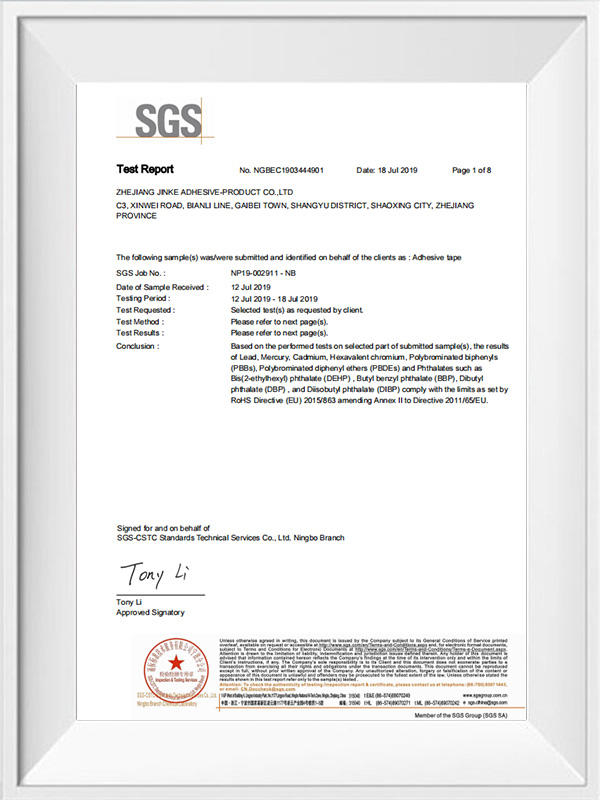

Non-toxic and non-flammable: Unlike some other types of adhesives, acrylic PSAs are generally considered to be safe and non-toxic. They are also non-flammable, which makes them safer to handle and transport.

Good UV resistance: Acrylic PSAs have good resistance to UV radiation, which makes them suitable for outdoor applications where exposure to sunlight is a concern.

Customizable properties: The properties of acrylic PSAs can be tailored to meet specific application requirements by adjusting the composition and formulation of the adhesive. This allows for a high degree of customization to ensure optimal performance in different environments and under different conditions.

Overall, acrylic pressure sensitive adhesives offer a combination of excellent performance, versatility, and safety that make them a popular choice for a wide range of applications.

The tack and adhesion strength of acrylic pressure sensitive adhesives (PSAs) can be influenced by a variety of factors, including:

Polymer composition: The chemical composition of the acrylic polymer used in the adhesive can affect the tack and adhesion strength of the PSA.

Molecular weight: The molecular weight of the acrylic polymer can also influence the tack and adhesion strength of the PSA. Higher molecular weight polymers tend to have higher adhesion strength.

Crosslinking density: Crosslinking density refers to the number of chemical crosslinks between polymer chains in the adhesive. Higher crosslinking density can result in higher adhesion strength.

Additives: Additives such as tackifiers, plasticizers, and fillers can be added to the adhesive formulation to improve the tack and adhesion strength of the PSA.

Substrate type: The type of substrate to which the PSA is applied can affect the adhesion strength. Different substrates may require different adhesion strengths, and the surface energy of the substrate can also affect the tack and adhesion strength of the PSA.

Environmental factors: Environmental factors such as temperature and humidity can also affect the tack and adhesion strength of the PSA. High temperatures can soften the adhesive, while high humidity can reduce the tack and adhesion strength.

Application method: The method of application can also affect the tack and adhesion strength of the PSA. Factors such as pressure, speed, and coating thickness can all influence the final properties of the adhesive.

By understanding these factors, adhesive manufacturers can adjust the formulation and processing conditions of acrylic PSAs to achieve the desired properties for specific applications.

Acrylic PSAs have several advantages over other types of adhesives. They have good resistance to aging, UV radiation, and weathering, and they can maintain their adhesive properties over a wide range of temperatures. They are also generally non-toxic and non-flammable.

Acrylic PSAs are commonly used in a wide range of applications, including tapes, labels, graphics, and medical devices. They can adhere to a variety of substrates, including plastics, metals, and glass, and can be used for both permanent and temporary bonding.

The properties of acrylic PSAs can be tailored to meet specific application requirements by adjusting the composition and formulation of the adhesive. This allows for a high degree of customization to ensure optimal performance in different environments and under different conditions.

There are several advantages of using acrylic pressure sensitive adhesives over other types of adhesives:

Good aging and weathering resistance: Acrylic PSAs are highly resistant to aging and weathering, which means they can maintain their adhesive properties over time and under exposure to different environmental conditions.

Versatile bonding: Acrylic PSAs can adhere to a wide range of substrates, including plastics, metals, glass, and fabrics.

Temperature resistance: Acrylic PSAs can perform well over a wide range of temperatures, making them suitable for use in both high-temperature and low-temperature applications.

Non-toxic and non-flammable: Unlike some other types of adhesives, acrylic PSAs are generally considered to be safe and non-toxic. They are also non-flammable, which makes them safer to handle and transport.

Good UV resistance: Acrylic PSAs have good resistance to UV radiation, which makes them suitable for outdoor applications where exposure to sunlight is a concern.

Customizable properties: The properties of acrylic PSAs can be tailored to meet specific application requirements by adjusting the composition and formulation of the adhesive. This allows for a high degree of customization to ensure optimal performance in different environments and under different conditions.

Overall, acrylic pressure sensitive adhesives offer a combination of excellent performance, versatility, and safety that make them a popular choice for a wide range of applications.

The tack and adhesion strength of acrylic pressure sensitive adhesives (PSAs) can be influenced by a variety of factors, including:

Polymer composition: The chemical composition of the acrylic polymer used in the adhesive can affect the tack and adhesion strength of the PSA.

Molecular weight: The molecular weight of the acrylic polymer can also influence the tack and adhesion strength of the PSA. Higher molecular weight polymers tend to have higher adhesion strength.

Crosslinking density: Crosslinking density refers to the number of chemical crosslinks between polymer chains in the adhesive. Higher crosslinking density can result in higher adhesion strength.

Additives: Additives such as tackifiers, plasticizers, and fillers can be added to the adhesive formulation to improve the tack and adhesion strength of the PSA.

Substrate type: The type of substrate to which the PSA is applied can affect the adhesion strength. Different substrates may require different adhesion strengths, and the surface energy of the substrate can also affect the tack and adhesion strength of the PSA.

Environmental factors: Environmental factors such as temperature and humidity can also affect the tack and adhesion strength of the PSA. High temperatures can soften the adhesive, while high humidity can reduce the tack and adhesion strength.

Application method: The method of application can also affect the tack and adhesion strength of the PSA. Factors such as pressure, speed, and coating thickness can all influence the final properties of the adhesive.

By understanding these factors, adhesive manufacturers can adjust the formulation and processing conditions of acrylic PSAs to achieve the desired properties for specific applications.

EN

EN  English

English 中文简体

中文简体