In order to ensure the quality stability of Bopp Jumbo Roll Tape during the production process, we need to conduct meticulous control from multiple dimensions. Below I will deeply modify and enrich the article to enhance its credibility and depth.

First of all, in terms of raw material quality control, we must strictly screen polypropylene particles and other functional additives. This means we need to establish long-term relationships with reliable suppliers and conduct regular quality checks on raw materials to ensure their purity and stability. At the same time, we should also pay attention to the storage conditions of raw materials to avoid them being affected by adverse factors such as moisture and pollution.

Secondly, the optimization of production lines is the key to achieving quality stability. We need to use advanced production equipment and technology to ensure that all aspects of the production process can be accurately controlled. This includes processes such as melt extrusion, stretching, solidification, cutting and packaging. By introducing automation and intelligent technology, we can reduce errors caused by human factors, improve production efficiency while ensuring product quality.

In terms of process parameter control, we need to accurately control various parameters during the production process. This includes key indicators such as temperature, speed, and stretch ratio. By formulating strict process specifications and operating standards, we can ensure that every step in the production process meets quality requirements. At the same time, we also need to establish a real-time monitoring and feedback mechanism to promptly discover and adjust abnormal situations in the production process.

In addition, establishing a complete quality management system is an important guarantee for ensuring quality stability. We need to formulate clear quality standards and inspection procedures, and set up a dedicated quality inspection department to be responsible for the supervision and inspection of product quality. At the same time, we also need to establish a defective product recording and processing system, handle and analyze unqualified products in a timely manner, find out the reasons and take effective measures to improve them.

In terms of employee training and management, we must not only focus on improving the technical level of employees, but also strengthen their quality awareness training. Through regular training and assessment, we can ensure that our employees are familiar with and comply with production specifications and quality standards. At the same time, we also need to establish an incentive mechanism to encourage employees to actively participate in quality improvement and innovation activities.

Finally, in terms of supply chain management, we need to establish long-term and stable cooperative relationships with suppliers and conduct regular evaluations of them. This helps us ensure that our suppliers always provide high-quality raw materials and that problems can be resolved promptly when they arise. In addition, we can reduce supply chain risks through diversified procurement strategies and ensure the stability of raw material supply.

In summary, by focusing on raw material quality control, production line optimization, process parameter control, quality management system construction, employee training and supply chain management, we can ensure the quality stability of Bopp Jumbo Roll Tape during the production process . This will help enhance the competitiveness of products, meet customer needs, and win a good reputation and market share for the company.

Web Menu

Product Search

Exit Menu

How to ensure the quality stability of Bopp Jumbo Roll Tape during the production process?

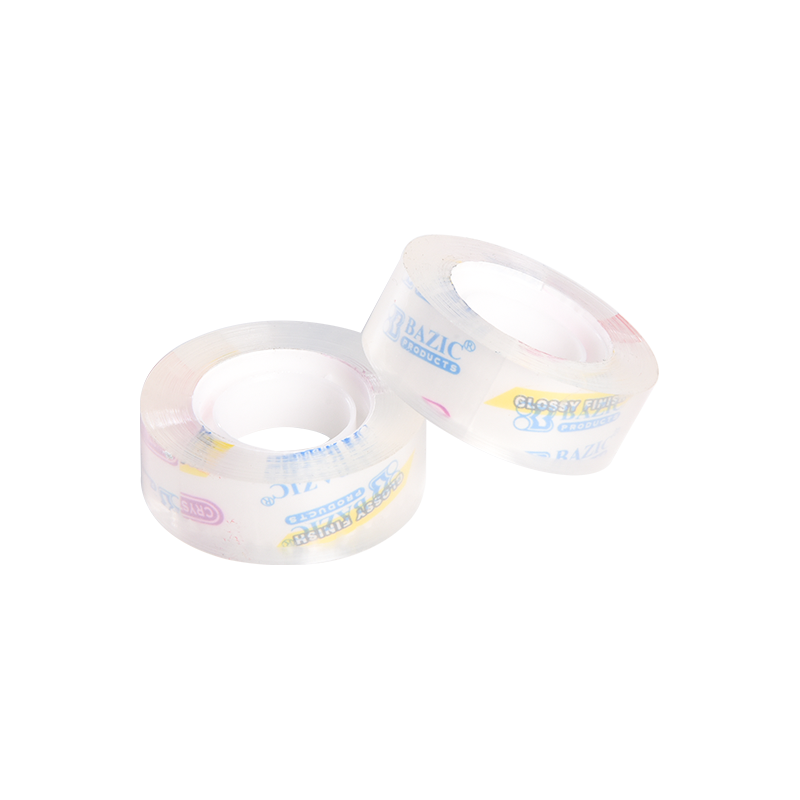

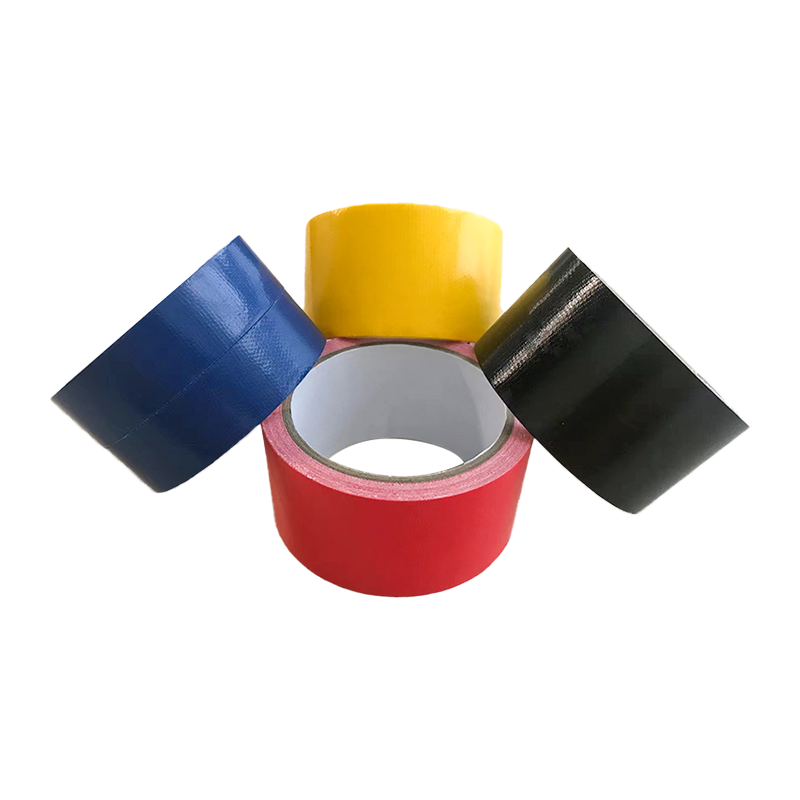

Recommended Products

Product Categories

Recommended Products

ZHEJIANG JINKE ADHESIVE PRODUCTS CO., LTD.

ZHEJIANG YUZHENG TECHNOLOGY CO., LTD.

Contact Us

-

Address:No.17, Kang Yang Avenue, Hangzhou Bay Economic and Technological Development Zone, Shangyu District, Shaoxing City, Zhejiang Province, China.

-

Tel: +86-575-82728668

-

Email: [email protected]

Copyright © Zhejiang Jinke Adhesive Products Co., Ltd. All Rights Reserved Wholesale Adhesive Products Manufacturers

EN

EN  English

English 中文简体

中文简体