Industry Knowledge Extension

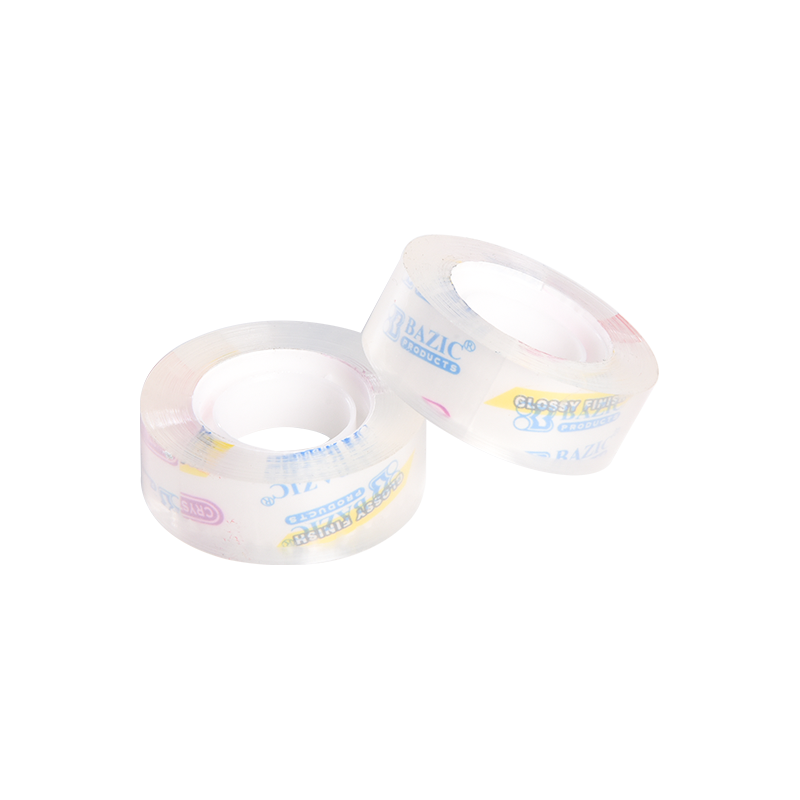

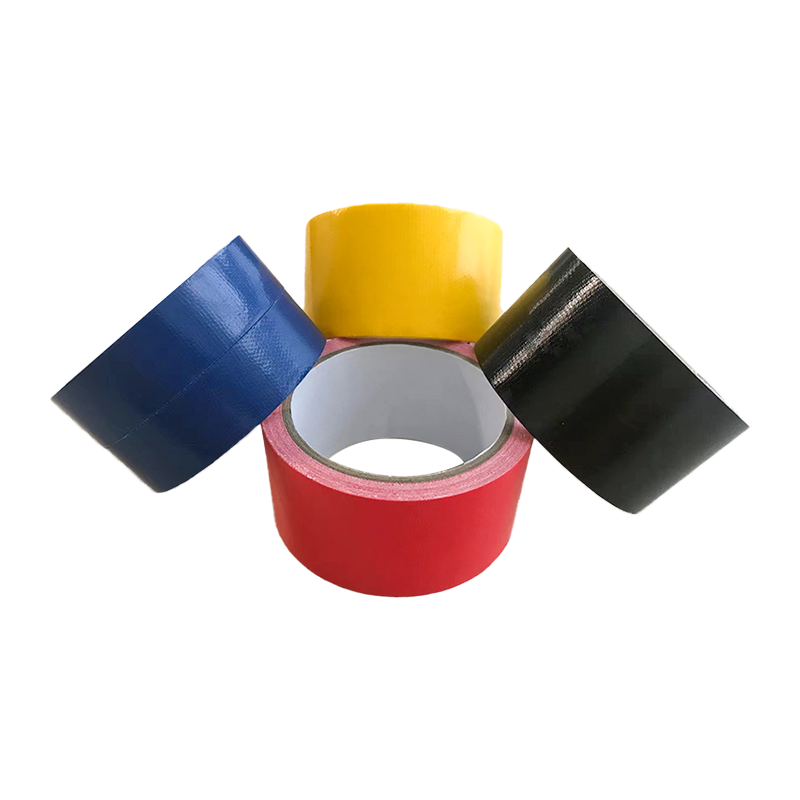

A paper core, also known as a paper tube or cardboard tube, is a cylindrical tube made of paper or cardboard. Paper cores are used in a variety of industries for packaging, storing, and transporting various products, such as textiles, films, tapes, and labels.

Paper cores can be made from different types of paper, including kraft paper, recycled paper, and specialty papers. They come in different sizes and thicknesses depending on the specific needs of the application. The cores can be customized with various features, such as printing, labeling, and moisture-resistant coatings.

In addition to their use in packaging and storage, paper cores are also used in various industrial applications, such as winding and unwinding materials on production lines. They can also be used as structural components in furniture and construction.

The recycling of paper cores is an important consideration, as they can be easily recycled and reused, reducing waste and environmental impact. Many manufacturers now offer recycled paper cores and actively promote sustainable practices in their production processes.

There are different types of paper used to make paper cores, depending on the specific application requirements. Here are some of the common types:

Kraft paper: This is a type of paper that is made from wood pulp and is known for its strength, durability, and stiffness. Kraft paper is commonly used for making paper cores for industrial applications, such as packaging and shipping.

Recycled paper: This is paper that is made from waste paper materials and is commonly used to make paper cores for eco-friendly applications. Recycled paper cores are not as strong as those made from virgin materials, but they are an environmentally sustainable option.

Specialty paper: This refers to paper that is specifically designed for certain applications, such as moisture-resistant paper, flame-resistant paper, or antistatic paper. Specialty paper cores are used in industries where the product being wound on the core requires specific handling or protection.

Coated paper: This is paper that is coated with a layer of material, such as polyethylene or wax, to improve its resistance to moisture, chemicals, or other factors. Coated paper cores are commonly used for food packaging, labeling, and other applications where the product needs to be protected from environmental factors.

Laminated paper: This is paper that is made by bonding multiple layers of paper together, creating a stronger and more durable material. Laminated paper cores are commonly used in heavy-duty applications, such as construction and furniture manufacturing.

The choice of paper type depends on the specific requirements of the application, such as strength, durability, moisture resistance, or environmental sustainability.

There are several advantages of using paper cores over other materials such as plastic or metal. Here are some of the main advantages:

Lightweight: Paper cores are lightweight, making them easier to handle and transport compared to heavier materials like metal.

Eco-friendly: Paper cores are made from renewable resources and can be easily recycled, making them a more environmentally sustainable option compared to plastic or metal.

Customizable: Paper cores can be easily customized with printing, labeling, and other features, making them a versatile option for a variety of applications.

Cost-effective: Paper cores are generally less expensive to produce compared to metal or plastic, making them a more cost-effective option.

Safe: Unlike metal, paper cores do not have sharp edges that can cause injury during handling or transport.

Insulating: Paper cores can provide some level of insulation, protecting the product inside from temperature fluctuations or other environmental factors.

Easy to use: Paper cores can be easily cut, bent, or shaped to fit specific applications, making them a user-friendly option.

Overall, paper cores offer a lightweight, customizable, cost-effective, and environmentally sustainable solution for a variety of applications.

Paper cores can be made from different types of paper, including kraft paper, recycled paper, and specialty papers. They come in different sizes and thicknesses depending on the specific needs of the application. The cores can be customized with various features, such as printing, labeling, and moisture-resistant coatings.

In addition to their use in packaging and storage, paper cores are also used in various industrial applications, such as winding and unwinding materials on production lines. They can also be used as structural components in furniture and construction.

The recycling of paper cores is an important consideration, as they can be easily recycled and reused, reducing waste and environmental impact. Many manufacturers now offer recycled paper cores and actively promote sustainable practices in their production processes.

There are different types of paper used to make paper cores, depending on the specific application requirements. Here are some of the common types:

Kraft paper: This is a type of paper that is made from wood pulp and is known for its strength, durability, and stiffness. Kraft paper is commonly used for making paper cores for industrial applications, such as packaging and shipping.

Recycled paper: This is paper that is made from waste paper materials and is commonly used to make paper cores for eco-friendly applications. Recycled paper cores are not as strong as those made from virgin materials, but they are an environmentally sustainable option.

Specialty paper: This refers to paper that is specifically designed for certain applications, such as moisture-resistant paper, flame-resistant paper, or antistatic paper. Specialty paper cores are used in industries where the product being wound on the core requires specific handling or protection.

Coated paper: This is paper that is coated with a layer of material, such as polyethylene or wax, to improve its resistance to moisture, chemicals, or other factors. Coated paper cores are commonly used for food packaging, labeling, and other applications where the product needs to be protected from environmental factors.

Laminated paper: This is paper that is made by bonding multiple layers of paper together, creating a stronger and more durable material. Laminated paper cores are commonly used in heavy-duty applications, such as construction and furniture manufacturing.

The choice of paper type depends on the specific requirements of the application, such as strength, durability, moisture resistance, or environmental sustainability.

There are several advantages of using paper cores over other materials such as plastic or metal. Here are some of the main advantages:

Lightweight: Paper cores are lightweight, making them easier to handle and transport compared to heavier materials like metal.

Eco-friendly: Paper cores are made from renewable resources and can be easily recycled, making them a more environmentally sustainable option compared to plastic or metal.

Customizable: Paper cores can be easily customized with printing, labeling, and other features, making them a versatile option for a variety of applications.

Cost-effective: Paper cores are generally less expensive to produce compared to metal or plastic, making them a more cost-effective option.

Safe: Unlike metal, paper cores do not have sharp edges that can cause injury during handling or transport.

Insulating: Paper cores can provide some level of insulation, protecting the product inside from temperature fluctuations or other environmental factors.

Easy to use: Paper cores can be easily cut, bent, or shaped to fit specific applications, making them a user-friendly option.

Overall, paper cores offer a lightweight, customizable, cost-effective, and environmentally sustainable solution for a variety of applications.

EN

EN  English

English 中文简体

中文简体